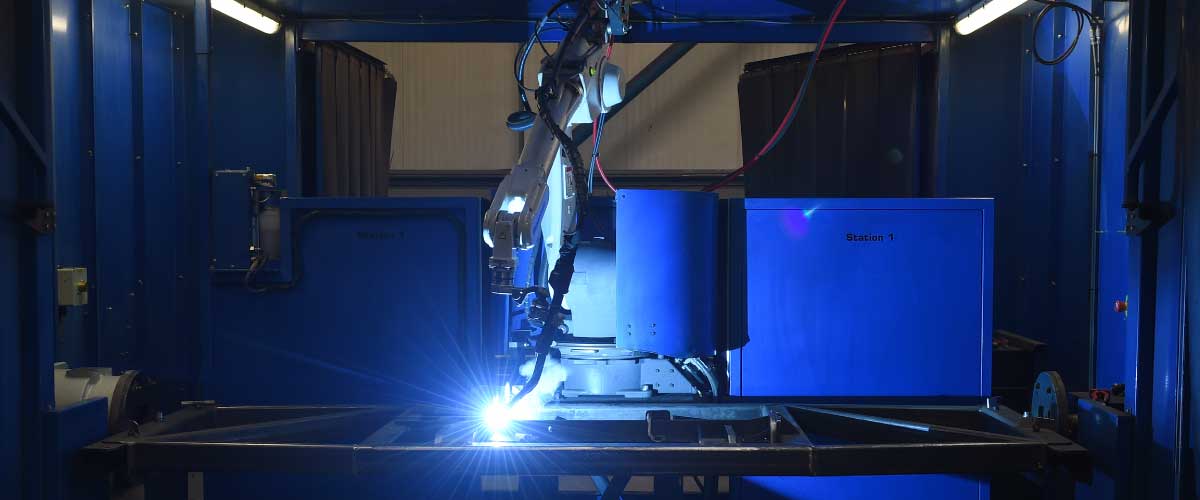

Investing in robotic welding technology

Over the past few years, Sherburn Metalwork has made substantial investments in robotic welding technology as a way of moving forward in new markets.

The Yorkshire-based engineering company was initially set up to manufacture bus chassis, but following continuous investments in state-of-the-art technology coupled with a team of highly-skilled engineers, Sherburn Metalwork has branched out into new markets such as the HGV trailer world.

Further to this, Sherburn also recently supplied to the UK military and opened up new opportunities in the MoD sector.

With 12 robotic welding cells now available across the Group, the company has improved its manufacturing speed, accuracy and repeatability as well as minimising costs for customers.

Recent investments include a robotic welding cell with a capability of welding 2.5m x 1m in 3D. It also boasts complete harmonic movement with jigs to manipulate weld seams to optimum angle.

As a way of improving efficiency, Sherburn Metalwork offer robotic welding as a 24 hour service, as well as an in-house jig design and build service.

Parent company WEC Group has made over £11m of investment in new machinery over the past 12 months. This includes investments in capital equipment, such as a fully automated six metre bed laser cutting machine, CNC machining and waterjet cutting technology.